38 thermal transfer labels definition

Thermal Transfer vs. Direct Thermal: Five Key Considerations Conversely, thermal transfer printing has thermal ribbon acting as a "buffer" between the print head elements and the label material. Many thermal ribbons are designed with a back-coating that serves to increase print head life by reducing static and friction. This benefit is not possible when direct thermal printing due to the lack of ribbon. avocetscales.co.zaAvocet – Scales & Labels Avocet Scales & Labels. Avocet Scales and Labels leads the way in the retail weighing arena. As a solely South African owned company with its Head Office, National Warehouse and Label Production facility, supplying its 10 strategically situated branches in South Africa.

Définition of thermal transfer printing | inkanto by ARMOR-IIMAK Thermal transfer is a fast printing process that allows the printing of variable data, controlled directly via dedicated software. This software connected to the printer transmits the data and printing information that will make each product unique.

Thermal transfer labels definition

The Dos and Don'ts of Labeling Specimens For Pathology Ideally, printed labels should be used with barcodes. It's handy to use a thermal-transfer printer with a smudge-proof resin ribbon, as the printout will resist most harsh solvents, such as formalin and alcohols, and won't rub off like pen or other types of ink would. DO attach the label properly so the barcode can be scanned Polypropylene (BOPP) Labels - Everything You Need To Know These thermal BOPP labels would come in one of two formats: Direct Thermal (no ribbon) or Thermal Transfer (ribbon required). The advantage of Direct Thermal labels is they do not require a ribbon to print. This means that you only need to inventory one supply item, as opposed to the two required for Thermal Transfer. Thermal-transfer printing - Wikipedia Thermal transfer is a popular print process particularly used for the printing of identification labels. It is the most widely used printing process in the world for the printing of high-quality barcodes. Printers like label makers can laminate the print for added durability. Thermal transfer printing was invented by SATO corporation.

Thermal transfer labels definition. What is thermal transfer printer? - Definition from WhatIs.com A thermal transfer printer is a non-impact printer that uses heat to register an impression on paper. A thermal transfer printer has a printhead containing many small resistive heating pins that on contact, depending on the type of thermal transfer printer, melt wax-based ink onto ordinary paper or burn dots onto special coated paper. Thermal printing - Wikipedia Thermal printing (or direct thermal printing) is a digital printing process which produces a printed image by passing paper with a thermochromic coating, commonly known as thermal paper, over a print head consisting of tiny electrically heated elements.The coating turns black in the areas where it is heated, producing an image. Most thermal printers are monochrome (black and white) although ... Understanding Thermal Labels: Direct Thermal vs. Thermal Transfer Thermal labels are the perfect solution for printing information on demand such as barcodes, ingredients and dates. There are two methods to consider, each with their own advantages; direct thermal and thermal transfer. Choosing the right thermal option requires matching application requirements with the capabilities of your printer. › custom-labelsCustom Printed Labels | Custom Label Printing | Labels Online Any shape, size, and design, we only use premium materials and production techniques to offer the best custom printed product labels on the market. Supplied on rolls, we built up both the technical knowledge and resources necessary to enable us to meet the individual needs of a truly diverse range of customers.

Adhesive Labels | Plain & Printed Label Manufacturer ... If you have at least 2 years’ experience in sales within the packaging industry and are interested in a new role, send your CV in the first instance to marketing@hamilton-labels.co.uk Reply on Twitter 1352177301115588608 Retweet on Twitter 1352177301115588608 Like on Twitter 1352177301115588608 Twitter 1352177301115588608 What are Thermal Labels? | Zebra What Are Thermal Labels? Thermal labels use heat to create an image. Thermal transfer uses a thermal ribbon where heat from the printhead releases the ribbon attaching it to the label surface. Direct thermal images are created when heat from the printhead causes components on the label surface to mix causing them to (usually) turn black. Thermal Ribbons — Thermal Label Warehouse LLC Thermal Ribbons Thermal transfer ribbons are arguably the most important piece of the thermal printing puzzle. That's why we only carry the best ribbons from top manufacturers like DNP, IIMAK, & ITW. These companies have set the standard when it comes to thermal transfer ribbons and they continuously raise the bar. Label Printing: Important Terms and Definitions | The Label Printers The process of impressing a design or image into (below) the label surface, adding another design element to the finished label. It often uses a set of matched rollers to create the desired effect. Die Cutting tool or device used for creating the desired shape of a label.

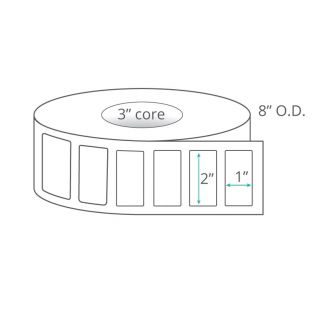

Home - TTP - Thermal Transfer Products Find a Thermal Transfer Product that can perform for you. I'm trying to cool. Using. In a system that is. Show my products. Product Overview Brochure View all products Not sure? Talk to an expert. Designed to keep you working. TTP is a leading manufacturer of pre-engineered heat exchangers for the fluid power industry. ... Permanent & Removable Adhesive Labels - Blanco Labels Blog Direct thermal and thermal transfer labels are 4" x 6" with a 3" or 1" core. Permanent cold temperature direct thermal labels using high quality top coated paper with a moisture barrier designed to be applied at below-freezing temperatures. Finishes include semi-gloss, high-gloss, and matte finishes. Thermal transfer | inkanto by ARMOR-IIMAK Thermal Transfer printing is a simple, performing and competitive printing technology that enables to print all types of labels and flexible packaging.. Definition What is Thermal Transfer Printing ? Applications Thermal Transfer: barcode and packaging printing Sustainable Performance Thermal Transfer Sustainable Performance Industrial printers Direct Thermal vs. Thermal Transfer Label Printers Thermal transfer printers require the use of a carbon ribbon which gets transferred onto the substrate via heat, hence the name "thermal transfer." The ribbons can be different colors, so the user is not limited to black print.

What is Thermal-Transfer? - LabTAG Laboratory Labels What is Thermal-Transfer? Thermal-transfer printing uses a ribbon to print information on labels. The heated print-head is used to melt the ink coating of the ribbon, transferring it to the label. Since the label itself is not reactive, the print produced by this method is much more stable and a lot more durable.

› wp-content › uploadsTroubleshooting Thermal Transfer Printing Problems Troubleshooting Thermal Transfer Printing Problems Possible Cause Corrective Action Poor Edge Definition (bar codes and alphanumerics) Print speed is too high Reduce print speed; do not rotate symbol Ribbon and media are incompatible Test alternative ribbon or media Bar Codes Smearing (bar code edges "bleeding" or "feathering")

Labelsontime Buy fanfold Labels for thermal transfer printing. Our collection of thermal labels for transfer printing in fanfold stacks is extensive. Most sizes with have a choice of both perforated and nonperforated and come with a permanent acylic adhesive. A variety of materials, adhesives and color thermal labels are available on 3" cores for your ...

Top-Coated Labels vs. Non-Coated Labels: The Difference Matters! There are many types of direct thermal and thermal transfer label face-stocks in the marketplace, from uncoated to full top-coated. In one of our previous blog posts we talked about how top-coated labels - which is the only face-stock that we use - will lower your total cost of ownership compared to uncoated labels. And while that's a major reason why you should switch to top-coated ...

en.wikipedia.org › wiki › ResistanceResistance - Wikipedia Thermal shock resistance, a measure of resistance of a material to temperature jumps. Thermal resistance, a measure of difficulty of heat transfer through a substance Thermal conductivity, how well heat is conducted through a substance; Thermal resistance in electronics, heat considerations in electronics design; Other uses

› us › enDirect Thermal and Thermal Transfer Printing | Zebra Thermal Transfer Printing. Thermal transfer printed labels are easily identified by the crisp, often glossy, printed surface. The clarity is achieved by using a thin ribbon roll that when heated by the printhead melts onto the label to form the image. The ink is absorbed so that the image becomes part of the media.

Label Adhesives Guide: Types and Properties | Label Printing Initial Tack: The immediate holding power of the label adhesive on contact with a specific surface. If initial tack is low, it will have low adhesion, allowing the label to be removed cleanly. Adhesives with a low initial tack will build up adhesion over time (i.e. the difference between removable and repositionable).

What is a thermal printer? (direct transfer) - Creative Safety Supply Thermal transfer printing occurs by a process that uses heat in order to produce an imagine on paper, a label, or some other such material. The image is created by melting a coating so that it stays glued to the intended material. This technique provides high-quality image printing that can't compare to other on-demand printing options.

What is a thermal transfer ribbon? | RICOH INDUSTRIE FRANCE SAS Thermal Transfer Ribbon is basically a polyester film on which are coated different layers. Ink layer is transferred to the label thanks to the heat delivered by the thermal head of the thermal printer. The different qualities of thermal transfer ribbons

Direct Thermal Labels VS. Thermal Transfer Labels: Know the Difference - L.G. Business Systems

Thermal Transfer vs Direct Thermal - Passion Labels Thermal Transfer: When Thermal Transfer printing, you are using a thermal ribbon, which acts as a buffer between the printhead and label material. Thermal ribbons are designed with an acrylic back-coating, that serves to increase printhead life, by reducing static and friction.

Thermal Transfer Labels- Lowest Price in the Industry Thermal transfer labels use a heat-sensitive carbon ribbon that is melted on onto the label. Unlike direct thermal labels, thermal transfer labels always require a thermal ribbon and are perfect for long-term packaging, warehousing, shipping, receiving, and inventory management applications.

UL Label Terms: UL 969 - UL Label Guy UL labels can then be printed at the plant (secondary printing) under the PGJI2 designation. Typically this is going to require a Thermal Transfer printer (Laser printed toner is not typically durable enough to survive the durability test) using an approved thermal ribbon. And thermal transfer printers are going to use rolls of materials.

up.codes › viewer › californiaChapter 7 Fire and Smoke Protection Features - UpCodes In determining the fire-resistance rating of exterior bearing walls, compliance with the ASTM E119 or UL 263 criteria for unexposed surface temperature rise and ignition of cotton waste due to passage of flame or gases is required only for a period of time corresponding to the required fire-resistance rating of an exterior nonbearing wall with the same fire separation distance, and in a ...

Post a Comment for "38 thermal transfer labels definition"